Eliet Super Prof Self Propelled Max

BLOW CHUTE

The Super Prof blow chute is a fine example of engineering. Its shape prevents turbulence and the design of the curve was based on the optimal trajectory of the fl ying chips. As a result the machine

has phenomenal propelling capacity. The choice for synthetics as the material for the blow chute was a very deliberate one: it is seamless, corrosion resistant, perfectly smooth and sound absorbing. Its low air resistance makes the chute less inclined to clog. The blow chute has a discharge height of 2 m - 8ft and a rotation span of 300°.

COLLAPSIBLE BLOW CHUTE

The blow-out level of the Super Prof is at 2 m - 8 ft. An important asset, as it allows you to blow the chips from any possible location to where you want to deposit them. To make sure that the height does not pose a problem for transport, the chute can be collapsed onto the machine and clamped in place. Its height is thus reduced to 1.45 m – 4.75 ft.

WHEEL DRIVE - SD

The wheels of the new Super Prof were equipped with a powerful wheel motor. The speed forward or in reverse is controlled with a simple movement from the pulse via a rotating handle on the handlebar. The more the handle is rotated forwards or backwards, the faster the machine moves in that direction. The wheel drive is so powerful that it takes only one man to load or unload the machine from a van or a trailer.

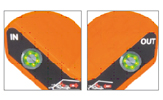

INFEED OPENING

The feed opening was made wide on purpose, but without compromising on the machine’s compactness. The feed hopper has become considerably larger mainly at the top. This makes for a larger feeding plateau, allowing the operator to place the green waste quicker and have both hands free to manipulate the waste. The special shape of the hopper walls pushes the waste towards the 45 cm wide central bottom of the hopper. This flat bottom does not get any narrower towards the feed roller. The feed roller can lift up to 13 cm, which creates a huge infeed opening. This feature is highly appreciated by professionals when they are feeding branches with many twigs or voluminous cutting waste.

INTELLIGENT MACHINE

All the features of the machine are grouped in a well-organised dashboard at the front of the machine. The large LCD screen stands out at the centre between the ignition key and the choke valve. It is via the LCD screen that the Super Prof communicates with its operator. Besides showing useful machine features, it tells the operator when maintenance is due. Below the display is the machine’s most essential button: the ‘ACTION’ button. This electronic control of the electromagnetic coupling engages the blade system and the Axelero™ and ensures that the feed roller can be activated. At one push of the button, the shredder beast comes to life.

EASY FEEDING

To ensure simple and intuitive control, the operating mechanism of the feed roller was separated clearly and visually. Push buttons within reach allow for selecting feed/reverse feed. Integrated LED lights in the button highlight the selection. One push of the emergency stop handle or one of the buttons will neutralise the selection and immediately stop the feed roller. This ultimate operating simplicity is a guaranteed time saver.

MINIMUM MANAGEMENT COSTS

The machine was developed from a low-maintenance perspective, so that checks and maintenance don't become time-consuming and dreaded activities. The Super Prof's internal management system helps to comply with the schedule. Regular maintenance keeps high repair costs at bay. The blade system is insensitive to foreign objects and its maintenance is simple and self-manageable. Only a limited number of parts are subject to wear and in addition, the machine has a high resale value as a second-hand item, which is an added bonus for its ROI.

MAXIMUM FLEXIBILITY AND TIME SAVINGS

The machine shreds wood as well as large volumes of green waste. The material does not have to be sorted beforehand. You drive the self-driving shredder to the location where you want to perform the shredding, which means that you don't lose any time supplying or removing materials.

MAXIMUM YIELD

The Eliet patented shredding system uses the weakness of the wood and therefore requires little motor capacity. The compact machine with its broad feeder also allows shredding branches of up to 13 cm thick as bundles of voluminous waste. Cutting waste does not have to be sorted prior to shredding. Branches don't require cutting before processing them in the machine. It all makes for gigantic time-savings.

The ABM system ensures that the engine always operates at maximum capacity and that fuel consumption never exceeds 3 litres per hour. The optional ECOEYE™ system lowers fuel consumption in passive operation mode, yielding another considerable saving. And finally the machine lowers your company's ecological footprint.

Performance |

|

| Engine selection | 18 HP B&S Vanguard |

| Number of cylinders | 2 |

| Cylinder capacity (cc) | 570 |

| Shreddable timberdiameter | 130 mm |

| Capacity | 6m3 chips/hour |

| Engine start system | electric |

| Cooling | air cooled |

| Shredding technology | ELIET Chopping PrincipleTM |

| Clutch | electromagnetic + brake |

| Blades | 6 disks, 24 blades ELIET RESISTTM/8 |

| Feed intake opening | 500 x 700 mm / 20"x28" |

| Feed height (mm / inch) | 1000 mm |

| Chopping movements/min. | 50.000 |

| Number of blades | ELIET RESISTTM/8 (24 pc.) |

| Discharge height | 2000 mm / 80" |

| Chassis | steel 3 & 4 mm / epoxy powdercoating |

| Wheel traction | 2 hydraulic engines (100 cc) |

| Front wheels | 4.00 -4 pneumatic tyre |

| Back wheels | 6.00 x 9 pneumatic tyres |

| Capacity of the fuel tank | 18 L |

| Cutting width | 480 mm |

| Transmission | V-belt XPA 2120 x2 Powerband |

| Feed assistance | hydraulic diam. 156 mm |

| Power control | ABM (Anti-Block Motor) |

Design |

|

| Dimensions (L x W x H in mm / inch) | 2000 x 835 x 1450 mm / 80x83x58" / low gravity point |

| Noise level Lw(A) | 116 dB(A) |

Options |

|

| Calibrating sieve | option - holes 35 x 35 mm |

| ECO EYE™ system | option |

| Speed controller for infeed roller | option |

| Agriculture Tires | |

If you would like to talk to one of our experts regarding this or any other product, just fill in the form below and one of our team will be in touch.